A novel metamaterial designed using AI to meet next generation requirements for rockets, missiles and other critical applications.

Arcarithm’s Artificial Intelligence and deep learning algorithms, plus a dynamic new metamaterial called EXO-Resin™, offer a rapid prototyping solution for designing components for the next generation of missiles and other critical space applications. EXO-Resin combines advanced AI with a resin-based metamaterial to quickly analyze design needs and recommend a resin/substrate formula that simultaneously tests multiple properties for dramatically reduced development time.

Material Attributes

- The base resin is extremely resistant to high temperatures.

- Any number of substrates can be added to the base resin to add new characteristics.

- Self healing.

- Structural toughness.

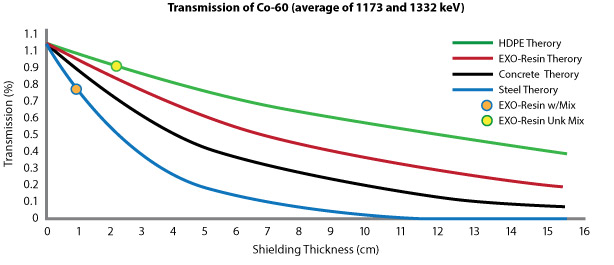

- EMF/Radiological resistance.

- Arcarithm AI determines the substrates and concentrations needed to meet requirements.

Rapid prototyping and component production are core characteristics of EXO-Resin. Additive and traditional manufacturing are easily incorporated in the component development process.

Component Development and Procurement Process

- Identify a component where conventional materials fall short of meeting requirements or an improved design would add value.

- Provide a spec of the desired component and performance requirements (thermal, structural, radiation tolerance).

- Arcarithm AI analyzes the requirements and provides a tailored formula of resin and substrate.

- Arcarithm provides a prototype component using the tailored resin formula for evaluation and transition to production.